Clean-in-place (CIP)

Heat exchangers play a major role in production processes, providing efficient and effective ways to transfer thermal energy. Clean-in-place (CIP) heat exchangers are especially useful in food and pharmaceutical production, as their stainless steel construction eliminates the possibility of bacterial growth that may occur with other materials. The CIP process begins by flushing out existing debris, before introducing sanitizing solutions such as hot water or heated cleaning chemicals. These high temperatures are able to break down any residue which has built up within the equipment. As well as eliminating bacteria, it is also designed to reduce operational costs since the equipment can be cleaned without disassembly.

- Sanitary and 3A Sanitary Certified: These heat exchangers meet stringent sanitary standards, including 3A Sanitary Standards, which ensure they are safe for use in food, beverage, and pharmaceutical applications.

- Efficient and Automated Cleaning: Clean-In-Place (CIP) technology allows for automated cleaning without disassembling the shell and tube heat exchangers, ensuring minimal downtime and higher productivity.

- Versatile Applications: Ideal for a variety of industries, CIP shell and tube heat exchangers are used in sanitary, 3A sanitary, and industrial sectors, making them highly versatile and adaptable to different processing environments.

- High Efficiency Heat Transfer: Designed to provide efficient heat transfer, these exchangers maintain optimal temperatures, improving the overall efficiency of thermal processes in various applications.

- Durability and Reliability: Constructed from high-quality materials such as stainless steel, these heat exchangers offer durability and long-term reliability, even in harsh industrial conditions.

- Compliance with Regulatory Standards: These heat exchangers are compliant with global regulatory standards, ensuring they meet all safety and quality requirements for industrial and sanitary processes.

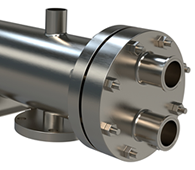

Sanitary 3A:

Food, Beverage and Pharmaceutical

- 3A Certified

- USDA & FDA Approved

- 304L or 316L Stainless

Sanitary:

Food & Beverage

- Cleanable & Drainable

- Sanitary Standard

- 304L or 316L Stainless

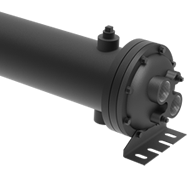

Non-Sanitary:

Non Food Related

- Industrial Applications

- Steel and Stainless Steel