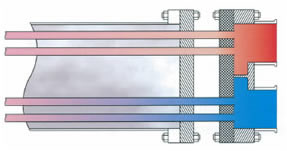

Double Tubesheet Exchangers

Double tubesheets are used for applications where the mixing of the tube-side fluid and the shell-side fluid must be avoided. In the event of leaks occurring where the extremities of the tubes are expanded into the tubesheet, the tube-side fluid would leak between the two tubesheets instead of leaking into the shell.

- Enhanced Safety: Double tube sheet heat exchangers are designed to prevent cross-contamination between fluids. This feature is crucial in industries where fluid mixing could lead to serious consequences.

- Leak Detection: The dual-tube sheet design provides an additional layer of protection by allowing for early detection of leaks. Any leakage is captured in the space between the two tube sheets, preventing it from contaminating the other fluid stream.

- Ideal for Critical Applications: These heat exchangers are commonly used in industries such as pharmaceuticals, chemical processing, and food and beverage where purity and safety are paramount.

- Compliance with Regulations: Many industries have strict regulations regarding contamination and leakage. Double tube sheet heat exchangers help companies comply with these standards, ensuring product quality and safety.

- Maintenance and Inspection: The design simplifies maintenance and inspection. Leaks and wear can be identified and addressed more easily, reducing downtime and maintenance costs.

- Efficiency: Though primarily designed for safety, double tube sheet heat exchangers also offer efficient heat transfer. This ensures optimal thermal performance while maintaining safety standards.

Double Tubesheet Applications

Double tube sheet heat exchangers are essential in many pharmaceutical, bio-tech, and related applications where product purity must be maintained by keeping fluids isolated from one another, thus safeguarding against contamination which could compromise efficacy or safety. In food processing, double tube sheet heat exchangers are critical for maintaining the integrity and safety of food products, preventing any potential contamination from process fluids, which is vital for consumer health and compliance with food safety regulations. The petrochemical sector also relies heavily on these heat exchangers, where they handle the separation of aggressive chemicals, ensuring no leakage occurs that could lead to hazardous reactions or environmental damage. Their role in maintaining the highest standards of operational safety and product quality underpins their necessity in these high-stakes environments.