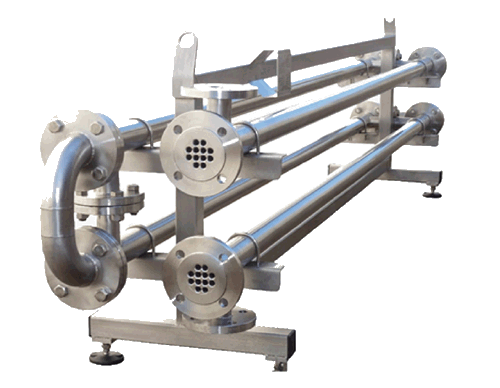

Tube in Tube Heat Exchangers

Tube-in-tube heat exchangers are particularly valued in industries such as food processing, pharmaceuticals, and chemical manufacturing, where a multi tube design would otherwise plug up. Additionally, tube-in-tube heat exchangers can handle high pressures and temperatures, making them versatile for various industrial needs.

- Sanitary Applications: The design reduces the risk of cross-contamination, making it ideal for sanitary applications.

- Handles High Pressures and Temperatures: Capable of operating under high pressure and temperature conditions, enhancing their usability.

- Adaptable Configurations: Available in various sizes and configurations to suit specific industrial requirements.

- Versatility: Suitable for a wide range of industries, including food processing, pharmaceuticals, and chemical manufacturing.

- Efficient Heat Transfer: The concentric tube design ensures a large surface area for effective heat exchange between the fluids.

- Easy Maintenance: The simplicity of the design allows for straightforward cleaning and maintenance, reducing downtime.

Tube-in-Tube Applications

Tube-in-tube heat exchangers find applications in many industries, but none more so than food processing where they are often used for pasteurization, cooling, and heating processes, ensuring consistent and safe handling of products like dairy, juices, pulps and sauces. The pharmaceutical industry relies on these heat exchangers for critical temperature control during the production of active pharmaceutical ingredients (APIs) and formulations, where maintaining precise conditions is essential for product integrity. Chemical manufacturing benefits from their ability to handle aggressive fluids and high-temperature operations, making them suitable for processes like condensation and vaporization.