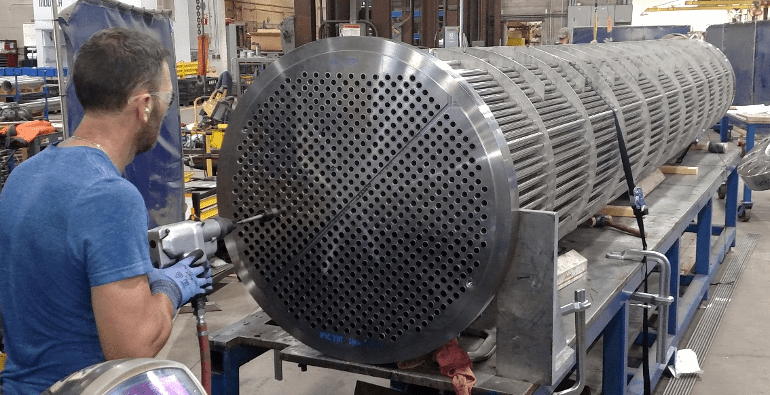

Fixed Tube Exchangers

Fixed tube sheet heat exchangers offer robust and efficient performance, ideal for applications requiring minimal maintenance and cost effective construction.

- Structure and Design: These heat exchangers feature a design where the tube sheets are welded or roller expanded directly to the tube sheet, providing a well-sealed and robust construction.

- Simplified Maintenance: The fixed tube sheet design allows for easy inspection and cleaning of the inside of the tubes, as they are straight and do not have a bend to contend with.

- Cost-Effective: With fewer parts and simpler construction compared to other designs, fixed tube sheet heat exchangers often come at a lower cost, making them an economical choice.

- Limited Thermal Expansion: One limitation is that fixed tube sheet designs do not accommodate thermal expansion between the shell and the tubes, which can be a drawback in applications with significant temperature variations.

- Customization Options: Fixed tube sheet heat exchangers can be customized in terms of size, tube length, and number of passes to meet the specific needs of different industrial processes.

- Material Flexibility: They can be constructed from a variety of materials, such as stainless steel, carbon steel, and other alloys, to meet specific process requirements and corrosion resistance needs.

Fixed Tube Applications

These exchangers are designed to withstand demanding conditions, making them an excellent choice for critical industries such as engine cooling, process applications and other industrial applications. Durability and efficiency ensure reliable operation, even under demanding conditions which is crucial for maintaining continuous operation. The fixed tube sheet design simplifies maintenance and inspection, further enhancing their appeal for applications where uptime and operational integrity are paramount.