Shell and Tube Heat Exchangers

Understanding the different types of shell and tube heat exchangers helps in selecting the right one for specific applications. U-tube heat exchangers manage significant temperature differences effectively. Tube-in-tube and hairpin designs are compact and efficient, suitable for limited space. Double tubesheet heat exchangers prevent cross-contamination, ideal for sensitive industries like pharmaceuticals. Fixed tube sheet heat exchangers are easy to clean but less suitable for high-temperature applications due to thermal stress. Regular replacement of bundles and gaskets is crucial for maintaining performance and longevity. Selecting the appropriate heat exchanger ensures efficiency and reliability.

- Fixed Tube Heat Exchangers: These exchangers have tubes that are fixed at both ends to the tube sheets, making them robust and easy to clean on the shell side. They are suitable for applications where the temperature difference between the fluids is relatively low, as significant thermal expansion can cause stress and potential damage to the tubes.

- U-Tube Heat Exchangers: These feature tubes bent into a U-shape, allowing for thermal expansion and contraction without causing excessive stress on the tubes. They are ideal for applications where one fluid is at a significantly higher temperature than the other.

- Tube-in-Tube Heat Exchangers: This design consists of an inner tube surrounded by an outer tube, with one fluid flowing through the inner tube and the other through the annular space between the tubes. This type is compact and efficient, suitable for small-scale applications.

- Hairpin Heat Exchangers: Also known as double-pipe heat exchangers, hairpin heat exchangers feature a pair of straight tubes connected by a U-bend, offering high efficiency in a compact form. They are often used in industries where space is limited.

- Double Tubesheet Heat Exchangers: Designed to prevent cross-contamination between the two fluids, double tubesheet heat exchangers have an additional barrier, making them suitable for applications requiring strict separation, such as in pharmaceuticals and food processing.

- Replacement Bundles and Gaskets: Over time, components of shell and tube heat exchangers may need replacement due to wear and tear. Replacement bundles (the tube assembly) and gaskets (seals between components) are essential for maintaining optimal performance and extending the lifespan of the equipment.

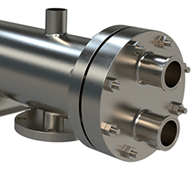

Sanitary 3A:

Dairy and Pharmaceutical

- 3A Certified

- USDA & FDA Approved

- 304L or 316L SSP

Sanitary:

Dairy, Food & Beverage

- Clean & Drainable

- Meets Sanitary Standards

- 304L or 316L SSP

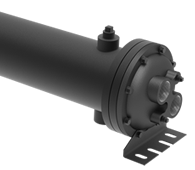

Industrial:

High Temperature Applications

- Steam to Water

- Carbon Steel or Stainless

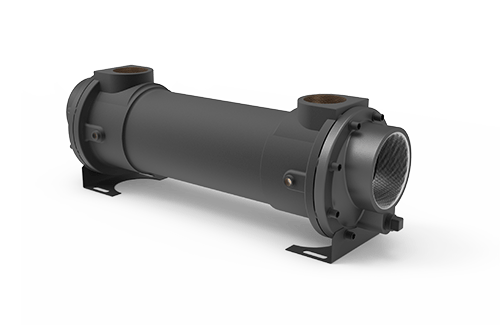

Shell & Tube Applications

Common applications include fluid processing, where they facilitate heat transfer between process fluids, everything from sanitary and pharmaceutical uses to engine and hydraulic oil cooling. They perform great in steam to water applications including CIP and vapor condensing and are especially useful for compressed air cooling. They typically handle several hundred PSI and temperatures over 250F but can be designed for even greater temperatures and pressures making them an indispensable option for many heat transfer applications.