U-Tube Exchangers

U-Tube shell and tube heat exchangers are a common design used in many industrial and sanitary applications due to their efficiency and versatility. This type of heat exchanger features a set of U-shaped tubes mounted within a cylindrical shell. One of the primary advantages of the U-Tube design is its ability to accommodate thermal expansion and contraction without causing stress on the tubes. This flexibility makes U-Tube heat exchangers particularly suitable for applications involving significant temperature differences between the two fluids. Additionally, the U-Tube configuration allows for easy maintenance and cleaning, as the tube bundle can be removed for inspection or repair.

- Thermal Expansion: The U-shape allows for better handling of thermal expansion and contraction, reducing the risk of thermal stress and extending the lifespan of the exchanger.

- Easy Tube Replacement: In the evenet of a tube failure, the U-Tube design allows for easier replacement of individual tubes without needing to dismantle the entire unit.

- Ideal for High Pressure: Suitable for high-pressure applications due to the sturdy construction and effective handling of pressure differences between the shell and tube sides.

- Enhanced Heat Transfer Efficiency: The design promotes efficient heat transfer by allowing multiple passes through the tubes, maximizing the heat exchange process.

- Versatile Applications: U-Tube heat exchangers are widely used in industries such as chemical processing, power generation, and oil refining, thanks to their ability to manage various fluids and gases efficiently.

- Corrosion Resistance: Often made from corrosion-resistant materials, U-Tube heat exchangers can handle aggressive fluids without significant wear, enhancing their operational life.

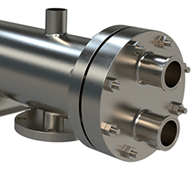

Sanitary 3A:

Dairy and Pharmaceutical

- 3A Certified

- USDA & FDA Approved

- 304L or 316L SSP

Sanitary:

Dairy, Food & Beverage

- Clean & Drainable

- Meets Sanitary Standards

- 304L or 316L SSP

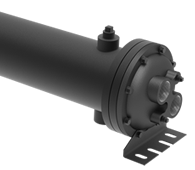

Industrial:

High Temperature Applications

- Steam to Water

- Carbon Steel or Stainless

U-Tube Applications

Industries such as food processing, bio-tech, pharmaceutical, chemical processing, steam to water applications, including CIP, where regular maintenance is crucial, and thermal expansion and contraction cycles are well tolerated. Because U-Tube heat exchangers are highly adaptable; they can be configured with various baffle types and tube layouts to optimize heat transfer performance. Whether it’s for cooling, condensing, or heating fluids, U-Tube shell and tube heat exchangers provide a reliable and efficient solution for a wide range of applications.