Heat Exchanger: Copper Nickel

Shell and tube heat exchangers commonly use materials like stainless steel, titanium, and Copper Nickel for tubing and tube sheets. The choice of material depends on the application requirements, including thermal conductivity, corrosion resistance, and mechanical strength.

- Corrosion Resistance: The material is highly resistant to corrosion, especially in seawater and other harsh environments, ensuring longer life and greater reliability.

- Stable Performance in Variable Conditions: Copper Nickel maintains stable thermal performance across a wide range of temperatures and pressures, making it suitable for diverse operational settings and environmental conditions.

- Durability: Copper Nickel exhibits high mechanical strength and durability, making it suitable for high-pressure and high-temperature applications.

- Low Thermal Expansion: The low thermal expansion coefficient of Copper Nickel reduces the risk of thermal stress and deformation, ensuring consistent and reliable performance even during temperature fluctuations.

- Compatibility with Other Metals: It is compatible with other metals commonly used in heat exchangers, preventing galvanic corrosion when combined with materials like stainless steel.

- Resistance to Stress Corrosion Cracking: Copper Nickel alloys resist stress corrosion cracking, which can be a critical factor in high-stress environments, enhancing the structural integrity of heat exchangers.

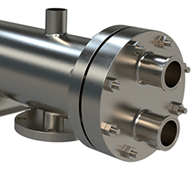

Sanitary 3A:

Dairy and Pharmaceutical

- 3A Certified

- USDA & FDA Approved

- 304L or 316L SSP

Sanitary:

Dairy, Food & Beverage

- Clean & Drainable

- Meets Sanitary Standards

- 304L or 316L SSP

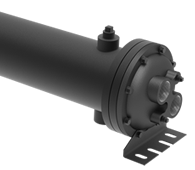

Industrial:

High Temperature Applications

- Steam to Water

- Carbon Steel or Stainless