Industrial Heat Exchangers

Industrial shell and tube heat exchangers are a critical component in many industrial processes, designed to transfer heat between two fluids efficiently. These devices consist of a cylindrical shell housing multiple tubes through which the fluids flow. One fluid runs through the tubes while the other flows over them within the shell. This arrangement allows for effective heat exchange, with the design being adaptable to various operational conditions such as high pressures and temperatures. Shell and tube heat exchangers are favored for their robustness, ease of maintenance, and scalability, making them a staple in industries for heating or cooling process fluids.

- Efficiency: These exchangers offer efficient heat transfer capabilities due to their large surface area, which facilitates maximum thermal energy exchange between fluids.

- Compatibility: Suitable for a wide range of fluids, including gases, liquids, and vapors, making them adaptable to various industries.

- Corrosion Resistance: Material options like stainless steel and titanium provide excellent resistance to corrosion, enhancing durability.

- Design: Shell and tube heat exchangers can be customized to meet specific operational requirements, including different pressure levels, temperatures, and fluid types.

- Scalability: They can be designed for small-scale operations or scaled up for large industrial applications, offering versatility in use.

- Maintenance and Cleaning: Easy to disassemble for routine maintenance and cleaning, ensuring long-term reliability and performance.

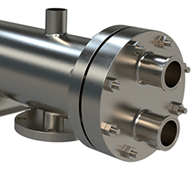

Sanitary 3A:

Dairy and Pharmaceutical

- 3A Certified

- USDA & FDA Approved

- 304L or 316L SSP

Sanitary:

Dairy, Food & Beverage

- Clean & Drainable

- Meets Sanitary Standards

- 304L or 316L SSP

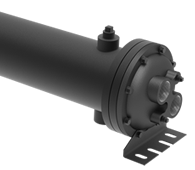

Industrial:

High Temperature Applications

- Steam to Water

- Carbon Steel or Stainless

Industrial Applications

In oil refineries, they facilitate the cooling and heating of various process streams, essential for refining crude oil into usable products. Chemical processing plants rely on these heat exchangers to manage exothermic and endothermic reactions, ensuring processes run smoothly while maintaining the required temperatures. In power generation, shell and tube heat exchangers are crucial for managing the thermal energy transfer in both conventional and nuclear power plants, significantly contributing to electricity production efficiency. Additionally, in the food and beverage industry, these heat exchangers ensure that heating and cooling processes maintain the quality and safety standards of edible products. Their role in marine applications is equally vital, providing engine cooling and other thermal management solutions aboard ships.