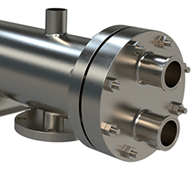

Heat Exchanger: 304 Stainless Steel

Shell and tube heat exchangers primarily utilize materials such as stainless steel, copper, and titanium. Each material offers unique benefits related to thermal conductivity, corrosion resistance, and mechanical strength, making them suitable for different industrial applications.

- Corrosion Resistance: 304 Stainless Steel offers excellent resistance to a wide range of corrosive environments, including acidic and alkaline solutions, which prolongs the life of the heat exchanger.

- Durability and Strength: 304 Stainless Steel has high tensile and yield strength, making it durable and able to withstand high pressure and mechanical stresses.

- Temperature Resistance: With the ability to endure high temperatures without degrading, 304 Stainless Steel is suitable for applications involving extreme heat.

- Hygienic Surface: The smooth and non-porous surface of 304 Stainless Steel is easy to clean and sanitize, which is crucial for applications in the food and pharmaceutical industries.

- Low Maintenance: The resistant properties of 304 Stainless Steel reduce the need for frequent maintenance and repairs, which translates to lower operational costs.

- Versatility: 304 Stainless Steel is versatile and can be used in various applications, including chemical processing, steam to water, and sanitary.

Sanitary 3A:

Dairy and Pharmaceutical

- 3A Certified

- USDA & FDA Approved

- 304L or 316L SSP

Sanitary:

Dairy, Food & Beverage

- Clean & Drainable

- Meets Sanitary Standards

- 304L or 316L SSP

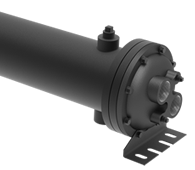

Industrial:

High Temperature Applications

- Steam to Water

- Carbon Steel or Stainless