Heat Exchanger: Food & Beverage

Shell and tube heat exchangers are indispensable for processes such as pasteurization, where precise temperature control is crucial for eliminating pathogens while preserving taste and nutritional value. They also support Clean-in-Place (CIP) operations, enabling thorough cleaning between production runs without disassembly, thus minimizing downtime and labor costs. In applications involving milk and dairy products, these heat exchangers ensure efficient heating and cooling, crucial for maintaining the delicate balance of flavors and textures. Additionally, they are used in reverse osmosis systems to preheat or cool fluids, enhancing the efficiency of the filtration process. For high viscosity fluids, shell and tube heat exchangers provide effective thermal management, ensuring smooth processing and consistent product quality.

- Pasteurization: These heat exchangers provide precise temperature control necessary for pasteurization, effectively eliminating harmful bacteria while maintaining the product's flavor and nutritional value.

- Clean-in-Place (CIP): Shell and tube heat exchangers support CIP operations, allowing for thorough cleaning of equipment between production runs without disassembly, reducing downtime and labor costs.

- Milk and Dairy: In milk and dairy applications, these heat exchangers ensure efficient heating and cooling, preserving the delicate balance of flavors and textures essential for high-quality dairy products.

- Reverse Osmosis: Used in reverse osmosis systems, shell and tube heat exchangers preheat or cool fluids, enhancing the efficiency of the filtration process and ensuring consistent product output.

- High Viscosity Fluids: Effective thermal management of high viscosity fluids is achieved through these heat exchangers, ensuring smooth processing and maintaining consistent product quality.

- Hygienic Design: The design of shell and tube heat exchangers ensures that there is no direct contact between the heating or cooling medium and the product, maintaining hygiene and preventing contamination.

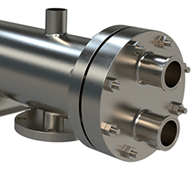

Sanitary 3A:

Dairy and Pharmaceutical

- 3A Certified

- USDA & FDA Approved

- 304L or 316L SSP

Sanitary:

Dairy, Food & Beverage

- Clean & Drainable

- Meets Sanitary Standards

- 304L or 316L SSP

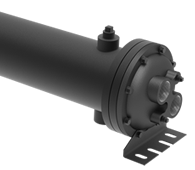

Industrial:

High Temperature Applications

- Steam to Water

- Carbon Steel or Stainless

Shell & Tube:Food and Beverage Applications

Text.