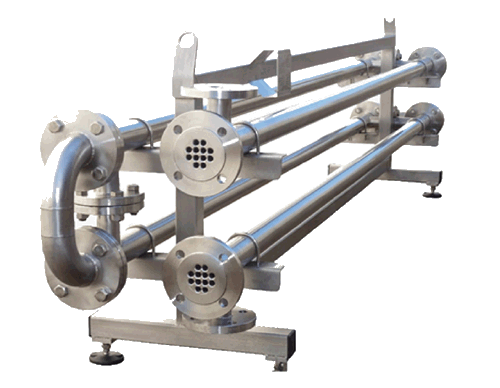

Hair-Pin Heat Exchangers

Offer a counterflow arrangement to maximize thermal efficiency and handle high pressures and temperatures, making them suitable for applications requiring a temperature cross.

- Compact and Versatile: Their compact design makes hair-pin heat exchangers ideal for installations with limited space. They can handle a variety of fluids and gases, making them versatile for different industries, including chemical and petrochemical.

- Efficient Heat Transfer: Hair-pin heat exchangers utilize a counterflow design that maximizes heat transfer efficiency, ensuring optimal performance in applications requiring precise temperature control.

- High Pressure and Temperature: Built to withstand extreme conditions, hair-pin heat exchangers are suitable for high-pressure and high-temperature operations, offering reliability and durability where it's needed most.

- Easy Maintenance: The modular structure of hair-pin heat exchangers allows for easy disassembly and cleaning, reducing downtime and maintenance costs. This design feature ensures long-term operational efficiency and ease of service.

- Temperature Cross: Due to the distance between inlet and outlet, a hairpin heat exchanger is considered the most efficient design for processes requiring a temperature cross, where the hot fluid outlet temperature is lower than the cold fluid outlet temperature.

- Energy Efficient: The efficient design of hair-pin heat exchangers reduces energy consumption, contributing to lower operational costs and a smaller carbon footprint, supporting sustainable and eco-friendly practices.

Hair-Pin Benefits

Hairpin exchangers are jacketed 'U' tube heat exchangers that operate with a true countercurrent flow, enabling effective temperature crossover where the hot fluid's exit temperature falls below the cold fluid's exit temperature. Available in both single tube (Double-pipe) and multiple tubes (Multi-tube) configurations, Double-pipe exchangers, which have a pipe within-a-pipe design, are ideal for high fouling services, like slurries with abrasive materials, and smaller tasks, with standard shell diameters ranging from 2” to 6”. Multi-tube exchangers are suited for larger duties, with shell diameters up to 30”. Options also include finned tubes, U-tubes, straight tubes with rod-thru capability, fixed tubesheets, and removable bundles. Hairpin units offer process advantages, providing a more economical and preferable solution for applications with extreme temperature crossings, high-pressure, low-pressure drop, and high-temperature requirements. Operationally, they facilitate easy mechanical cleaning on the shell side due to the removable bundle. They also offer flexibility, allowing Double Pipe Hairpins to accommodate changes in stream flow rates or conditions. Unlimited sections can be reconfigured in parallel and series to adapt to new conditions.