3A Sanitary Heat Exchangers

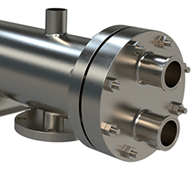

3A Sanitary Shell and Tube Heat Exchangers are designed to meet the stringent hygiene and cleanliness standards demanded by industries such as food and beverage, pharmaceuticals, and biotechnology. These heat exchangers consist of a series of tubes, one set carrying the product while the other set carries the heating or cooling medium. This configuration allows for efficient thermal transfer while maintaining product purity. The 3A certification ensures that these devices are constructed with materials and finishes that prevent contamination and facilitate easy cleaning, making them ideal for processes requiring high levels of sanitation.

- 3A Standard: Designed to meet stringent 3A sanitary standards, ensuring safety, cleanliness and product consistency.

- Construction: Made from high-grade stainless steel to prevent corrosion and contamination.

- Versatile Applications: Suitable for a variety of industries including food and beverage, pharmaceuticals, and biotechnology.

- Easy to Clean: Constructed for easy dismantling and cleaning, meeting CIP (clean-in-place) and SIP (sterilize-in-place) protocols.

- Temperature Control: Provides precise temperature regulation critical for processes in sensitive industries.

- Scalable: Available in various sizes and configurations to meet different process requirements.

Sanitary 3A:

Dairy and Pharmaceutical

- 3A Certified

- USDA & FDA Approved

- 304L or 316L SSP

Sanitary:

Dairy, Food & Beverage

- Clean & Drainable

- Meets Sanitary Standards

- 304L or 316L SSP

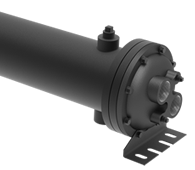

Industrial:

High Temperature Applications

- Steam to Water

- Carbon Steel or Stainless

3A Sanitary Applications

3A Sanitary Shell and Tube Heat Exchangers are versatile and widely used across various industries. In the food and beverage sector, they are essential for pasteurization, sterilization, and maintaining precise temperature control in processes like brewing and dairy production. In the pharmaceutical industry, they ensure that medicines and other products are produced under strict hygienic conditions, helping maintain efficacy and safety. Additionally, these heat exchangers are employed in biotechnology for processes that require meticulous temperature management and contamination prevention.