Heat Exchanger: 316 Stainless Steel

316 Stainless Steel is widely used in shell and tube heat exchangers due to its excellent corrosion resistance, high-temperature strength, and overall durability. It ensures optimal performance and longevity even in the most demanding industrial environments.

- Superior Corrosion Resistance: 316 Stainless Steel offers outstanding resistance to various forms of corrosion, including pitting and crevice corrosion, which is crucial for maintaining the integrity of the heat exchanger in aggressive environments.

- Versatility: This material is suitable for a wide range of applications, including chemical processing, petrochemicals, pharmaceuticals, food and beverage processing, and marine industries, making it a versatile choice for various industrial needs.

- High-Temperature Strength: The material performs exceptionally well at elevated temperatures, allowing for efficient heat transfer and maintaining structural stability under thermal stress.

- Hygienic Properties: 316 Stainless Steel is easy to clean and sterilize, making it ideal for use in industries where hygiene is paramount, such as food and beverage processing and pharmaceuticals.

- Durability and Longevity: The robustness of 316 Stainless Steel ensures a longer lifespan for heat exchangers, minimizing downtime and reducing the costs associated with frequent maintenance and replacements.

- Resistance to Scaling and Fouling: The material's smooth surface minimizes the risk of scaling and fouling, which can impede heat transfer efficiency and lead to higher operational costs.

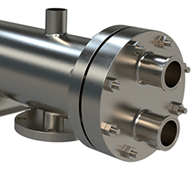

Sanitary 3A:

Dairy and Pharmaceutical

- 3A Certified

- USDA & FDA Approved

- 304L or 316L SSP

Sanitary:

Dairy, Food & Beverage

- Clean & Drainable

- Meets Sanitary Standards

- 304L or 316L SSP

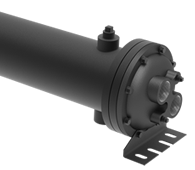

Industrial:

High Temperature Applications

- Steam to Water

- Carbon Steel or Stainless