Heat Exchanger: Brass and Bronze

Shell and tube heat exchangers commonly use a variety of materials for different components to optimize performance and durability. Brass and bronze are frequently utilized for tubes, tube sheets, and bonnets due to their excellent thermal conductivity, corrosion resistance, and mechanical strength.

- Corrosion Resistance: Both materials are resistant to corrosion, making them ideal for use with water and other corrosive fluids, thus prolonging the lifespan of the heat exchanger.

- Mechanical Strength: The mechanical strength of brass and bronze ensures that the heat exchangers can withstand high pressure and temperature conditions without deforming or failing.

- Durability: Heat exchangers made from these materials tend to have a longer service life due to their robust physical properties and resistance to wear and tear.

- Compatibility with Other Materials: Brass and bronze can be easily combined with other materials used in heat exchangers without adverse reactions, ensuring seamless integration and functionality.

- Reduced Maintenance Downtime: The strength and durability of brass and bronze minimize the need for frequent repairs, reducing maintenance downtime and ensuring uninterrupted operation of the heat exchangers.

- Thermal Expansion: Brass and bronze have moderate coefficients of thermal expansion, which means they handle changes in temperature better without significant expansion or contraction. This quality helps in maintaining the structural integrity of the heat exchanger under varying operational temperatures.

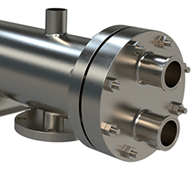

Sanitary 3A:

Dairy and Pharmaceutical

- 3A Certified

- USDA & FDA Approved

- 304L or 316L SSP

Sanitary:

Dairy, Food & Beverage

- Clean & Drainable

- Meets Sanitary Standards

- 304L or 316L SSP

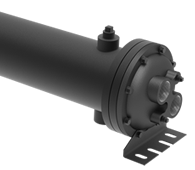

Industrial:

High Temperature Applications

- Steam to Water

- Carbon Steel or Stainless