Double Tube Heat Exchangers

Double tubesheet and double-tube heat exchangers provide enhanced safety by preventing cross-contamination between fluids, making them essential in industries requiring high purity.

- Design and Construction: Double tube heat exchangers consist of one tube inside another. The hot fluid flows through the inner tube, while the cold fluid flows through the outer tube, enabling efficient heat transfer.

- Versatility: They can handle various fluids, including gases, liquids, and even mixtures, making them suitable for a wide range of industrial applications.

- Low Maintenance: Double tube heat exchangers generally require minimal maintenance, reducing downtime and operational costs.

- Robust and Durable: They are typically constructed from stainless steel or other durable materials, ensuring long-lasting performance even under harsh conditions.

- Leakage Prevention: The double tube design provides an additional layer of protection against leaks, enhancing safety, especially when handling hazardous materials.

- Customizable: They can be customized to meet specific thermal and spatial requirements, ensuring optimal performance for unique industrial processes.

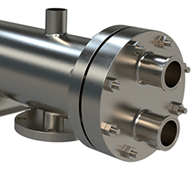

Sanitary 3A:

Dairy and Pharmaceutical

- 3A Certified

- USDA & FDA Approved

- 304L or 316L SSP

Sanitary:

Dairy, Food & Beverage

- Clean & Drainable

- Meets Sanitary Standards

- 304L or 316L SSP

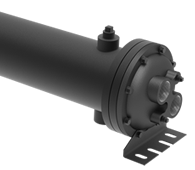

Industrial:

High Temperature Applications

- Steam to Water

- Carbon Steel or Stainless

Double Tube Applications

Double tube heat exchangers are vital in industries like pharmaceuticals, bio-tech, food processing, and petrochemicals, where product purity and safety are critical. In pharmaceuticals and bio-tech, these devices keep fluids isolated to prevent contamination that could compromise product efficacy and safety. In food processing, they maintain food integrity and safety, preventing cross-contamination from process fluids, which is crucial for consumer health and compliance with safety regulations. The petrochemical sector relies on these heat exchangers to handle aggressive chemicals, ensuring no leaks lead to hazardous reactions or environmental damage. Their role in ensuring operational safety and product quality underpins their necessity in these high-stakes environments.