Stainless Steel Heat Exchangers

304 stainless is often used for its excellent corrosion resistance and affordability, while 316 stainless offers enhanced resistance to chlorides and is ideal for more corrosive environments. Duplex stainless steel combines the best properties of both, providing superior strength and corrosion resistance, particularly in chloride-rich environments.

- Operational Environment: Assess the specific conditions the heat exchanger will face, such as temperature, pressure, and exposure to corrosive substances. Choose a stainless steel grade that best mitigates risks of corrosion and material failure in these conditions.

- Temperature Ranges: Ensure the stainless steel selected can maintain its properties at the temperatures your process demands. 316 stainless steel and duplex stainless steel generally offer better performance at higher temperatures compared to 304 stainless steel.

- Experience and Historical Performance: Consider the performance history of different stainless steel grades in similar applications. Proven success in comparable conditions can guide the selection process and increase confidence in material performance.

- Required Strength and Durability: Determine if the increased mechanical strength of duplex stainless steel could allow for thinner walls and lighter components, saving on material and installation costs. Evaluate the mechanical stresses the heat exchanger will endure during operation.

- Customization Options: Assess whether your application involves thermal cycling, which imposes stress on materials due to expansion and contraction. Duplex stainless steel offers lower thermal expansion, providing better dimensional stability under changing temperatures.

- Thermal Expansion and Cycling: Balance initial material costs with long-term savings from durability and reduced maintenance. For less aggressive environments, 304 stainless steel may offer the best cost-efficiency.

304 Stainless:

Industrial & Sanitary

- Least Expensive

- Resists Oxidation

- Moderate Temp Applications

316 Stainless:

Dairy, Food & Beverage

- Enhanced Corrosion Resistance

- Improved Resistance to Pitting

- Suitable for High-Temperature

Duplex Stainless:

High Purity & Pharmaceutical

- Exceptional Resistance to Corrosion

- Twice the Strength of Stainless

Industrial (Non Sanitary)

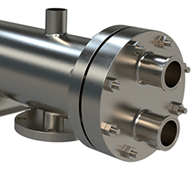

Stainless Steel Shell & Tube Applications

Non-sanitary shell and tube heat exchangers are utilized in heavy industries such as chemical manufacturing, CIP, and steam applications. These heat exchangers are designed to handle high pressures and temperatures, making them ideal for processing harsh and corrosive fluids.

Sanitary

Stainless Steel Shell & Tube Applications

Sanitary shell and tube heat exchangers are primarily used in the food and beverage industry, where hygiene and ease of cleaning are paramount. These units are constructed with smooth surfaces and materials that resist bacterial growth, ensuring safe and contamination-free heat transfer.

3A Sanitary

Stainless Steel Shell & Tube Applications

3A sanitary shell and tube heat exchangers adhere to stringent 3A sanitary standards, which are specific to the dairy and food processing industries in the United States. These exchangers ensure the highest levels of cleanliness and are designed for easy disassembly and cleaning to prevent contamination.

Pharmaceutical

Stainless Steel Shell & Tube Applications

Pharmaceutical shell and tube heat exchangers are engineered to meet the rigorous standards required for drug production and bioprocessing. These exchangers ensure precise temperature control and are constructed with materials that prevent leaching and maintain the purity of sensitive pharmaceutical compounds.